Recently, Prof. Wang Jianguo from the Amorphous Alloy Forming and Manufacturing Engineering Research Center of the School of Mechanical Engineering, DGUT worked with Prof. Yang Yong and his team from City University of Hong Kong, and together, they discovered a new mechanism of Elinvar effect in a quinary alloy system. This provides a new perspective for people to understand, study, and use this kind of material. On February 9th, 2022, this research was published online in Nature, a top international journal, with Prof. Wang Jianguo as co-first author and DGUT as the second completion unit.

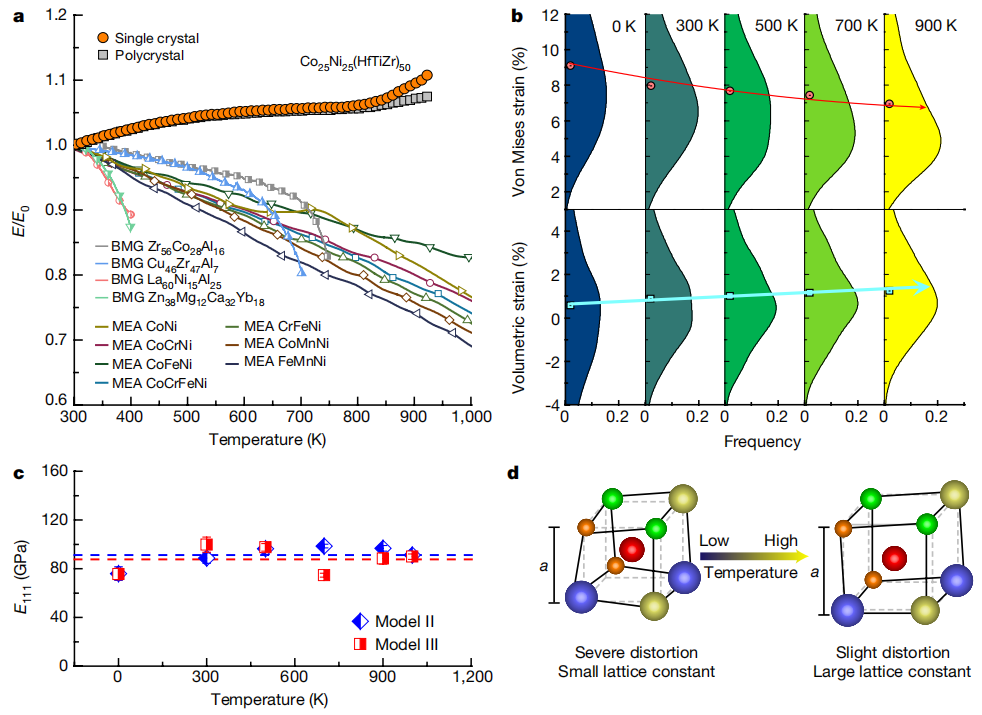

The elastic modulus of most materials decreases with increasing temperature; this is known as “thermal softening.” However, the elastic modulus of some materials remains the same or even rises slightly over a range of temperatures with invariable elasticity, and this is known as the “Elinvar effect.” Charles-Edouard Guillaume, a Swiss physicist, won the Nobel Prize in Physics in 1920 for his remarkable work on Elinvar alloy. There are two microphysical mechanisms for the origin of Elinvar effect—phase transition and elastic anisotropy. In some alloy systems, the temperature coefficients are significantly different along the elastic moduli of different crystal directions, and the disordered directions of a large number of grains in the material offset each other, resulting in the Elinvar effect. However, the temperature range at which the Elinvar effect occurs in those materials is narrow and is generally less than 100 K, hence, the temperature range for utilizing the materials is very limited.

The Elinvar effect has been found in the quinary alloy Co25Ni25 (HfTiZr) 50 (at.%), with an ultra-wide temperature range of about 600 K. This alloy system not only shows a physical mechanism different from any other Elinvar effect previously recognized, it is also a new alloy with the widest temperature range of the Elinvar effect so far.

Due to the serious lattice distortion, the dislocation motion of the alloy is hindered by the high energy potential barrier and thus exhibits extremely high elastic limit and very low energy dissipation. Due to its super-elasticity and elastic modulus stability under extreme temperature conditions, the alloy can be used in high-precision equipment with an extremely broad range of service temperatures, such as precision instruments, optoelectronic devices, deep space exploration, and other fields.

This research was supported by the National Natural Science Foundation of China (52071081), the Science and Technology Department of Guangdong Province (2019B030302010), and Dongguan University of Technology (216112008).

(Paper link: https://www.nature.com/articles/s41586-021-04309-1)

![]()